It started with a simple idea. Creating a leatherette in the purest shade of white. But white is never just white. It’s complex, changing under different lighting and environments.

“White requires extra work to continue to look good over the years. Our leatherette had to be more resilient, and we had to reexamine everything from our surface finishing method to the dye we used,” says Vincent Sin, Head of Industrial Design at Secretlab.

But making leatherette more durable can also make it less supple. We wanted to improve on the softness of our leatherette without compromising its strength — and getting there meant solving a fundamental materials challenge, which required us to rethink leatherette from the ground up.

Stronger from the inside out

For the past decade, we’ve been hard at work developing more advanced and durable leatherettes. Leatherette doesn’t like moisture — but it inevitably comes into contact with it when we perspire. So we set out on a 3-year research program with the Agency for Science, Technology and Research (A*STAR) to develop a leatherette tailored for warm, humid climates. Secretlab PRIME™ 2.0 PU Leatherette was our first bespoke leatherette formulation, setting a new benchmark for durability and effectively quadrupling the lifespan of PU leather.

But it didn’t end there. Most PU leathers have three layers, with a weak middle foam layer that is susceptible to moisture, particularly in humid climates. When moisture seeps in over time, it breaks down the structure and causes peeling.

To improve on PRIME™ 2.0 Leatherette and create an even more durable leatherette, we removed the middle layer entirely, and reinforced the base layer with high-density polyester fibers for a stronger foundation. This approach helped us make Secretlab NEO™ Hybrid Leatherette 12x more durable than regular PU leather.

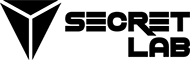

However, as we continued to push the toughness of leatherette further in our lab, we noticed that it became stiffer to touch. The solution was ultra-fine nanofibers, far smaller than the fibers used in its predecessor, woven into both the surface and base layers through an advanced needle-point process. The result is a material that’s incredibly resilient, yet addictively soft to touch. Don’t believe it? Experience it for yourself.

“In materials science, softness and durability usually work against each other. Softer materials tend to wear out faster, while tougher materials feel coarse,” says Vincent. “Secretlab NanoGen™ Hybrid Leatherette bridges that gap. It’s smooth and supple, but 14x more durable than standard PU leather.”

Pure precision

The nanofibers do more than just improve durability. They also allow for deeper, more uniform pigment penetration. With conventional synthetic leathers, color is applied as a surface coating, which can crack or fade over time. Secretlab NanoGenTM Hybrid Leatherette is different. Our proprietary dye coating process bonds pigment directly to individual nanofibers, creating a rich, stain-resistant finish that lasts for years.

This approach was especially critical for our Pure White colorway. Stains and UV discoloration show up prominently on white — and we wanted your chair to continue to look good for years. NanoGenTM Hybrid Leatherette also features enhanced UV resistance, where it has been subject to accelerated exposure in a UV chamber to ensure it maintains its color without yellowing.

But achieving the right shade of white wasn’t just about the leatherette itself — the colors had to be matched seamlessly across every component of the chair, from the plastic and metal, right down to the stitching. Shop now and discover the level of attention that went into every design decision we made.

“Different materials react to light in their own ways, so we meticulously calibrated individual finishes to create perfect visual harmony. Even the embossed TPU logo badge went through multiple refinements to blend flawlessly into the design,” says Vincent.

No room for error

Maintaining this level of quality in mass production meant rethinking our entire process. We established a dedicated production line with strict contamination controls to preserve the pristine white finish. Each chair undergoes a meticulous hand-inspection process, ensuring every detail meets our exacting standards before it leaves the factory.

Secretlab TITAN Evo NanoGen™ Edition was crafted not just to look extraordinary, but to stand the test of time. By reinventing leatherette from the inside out, we’ve created an upholstery that’s softer, brighter, and more durable than ever before. And when you run your fingers over it, you’ll feel the difference immediately.